RAMVAC HX-3

MID SIZE HYDRO EXCAVATION TRUCK

RAMVAC HX-3 HYDRO EXCAVATION TRUCK

The RAMVAC HX-3 is the smallest model in the RAMVAC family of hydro excavation trucks but is equipped with large productivity features. These single axle configuration units offer 3 cubic yard debris bodies and a boom reach of 11 to 16 feet with a 320-degree working radius. The 6″ vacuum system for these units feature a 3000CFM and 8″ blower capacity, as well as cyclone separation, a vacuum enhancer, directional discharge, hydrostatic blower drives, and a 10-micron final filter. For the water system, the HX-3 features a 325-gallon water capacity, a 10 GPM @ 2500 PSI pump, a 400,000 BTU water heater, all in an 80,000 BTU heated enclosure. The HX-3 also boasts compact footprints, NEMA rated electrical systems, debris blow-off systems and fully hydraulic power trains for superior reliability.

Quick Look at Specifications

GVWR 33,000 lbs

Min HP 300 hp

Capacity 3 yd

Boom Reach 11‘ - 16’

Axle Configurations: Single or Tandem Axle

Length 27‘ Width 8’ Height 12’

Easy Matainence

The RAMVAC truck-mounted vacuum excavator is built from the ground up to be the safest, simplest, and most maneuverable vacuum excavator on the market. When RAMVAC engineers began designing the HX truck-mounted series, they called on end users like you to help them understand what is important in the field and on the road.

RAMVAC understands that operators need a truck that can be easily maintained in the field with locally available parts. The trucks in the HX series are made with easily understood electrical systems and do not rely on complex computer systems. Owners are looking for a competitive advantage and RAMVAC offers trucks with better fuel standard vacuum tubes. economy and more reliable drive systems.

Designed for Productivity

With many available options, the RAMVAC HX series can be customized to meet the needs of any operator. RAMVAC’S HX series trucks are available with 3,000 to 5,400 CFM blowers, 6″ and 8″ systems, 3-yard to 15-yard debris tanks, and transfer cases or hydrostatic drives. RAMVAC’s Central Lubrication System and additional available 800,000 BTU water heater are features that set RAMVAC apart from the competition while helping operators get the job done right the first time.

The air filtration system is another key to RAMVACs’ industry-leading performance. Its design delivers high-performance air movement and maximum blower protection. RAMVAC’s standard Dig Deep boom increases operator productivity by providing the ability to dig 13 feet below grade utilizing one vacuum tube.

Exclusive Features

RAMVAC HX truck series comes equipped with many exclusive features that set it apart from its competition. The exclusive temperature-controlled environmental chamber protects against water system freezing. This allows you to utilize the truck in all climates, whether it be in an oilfield in South Texas or in the Canadian Tar Sands. This enclosure also provides security for all components inside the chamber. The design of the RAMVAC HX series ensures one of the smallest footprints in the industry, allowing operators to maneuver in and out of areas that competitor trucks cannot.

Our goal is to build a truck for you, that not only meets your needs but exceeds your expectations. RAMVAC puts operator safety and simplicity at the top of the list and is committed to building machines of the highest caliber to ensure the quality performance you require to reduce downtime and keep you profitable.

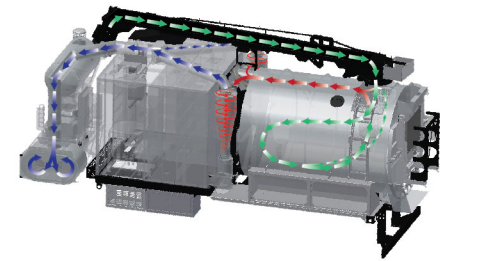

RAMVAC AIR SYSTEM

The RAMVAC Air System is the secret behind our industry-leading performance. The RAMVAC Air System is designed to deliver industry-leading air movement while providing the maximum protection for your blower.

The first stage in the RAMVAC Air System is airflow through the boom. The material will impact the back of the receiver box and start to drop into the tank. As the material enters the tank, it is directed toward the front of the tank to provide for even distribution. The air entering the tank along with the material is routed from the single 8″ entry point to dual 8″ exit points located at each side of the entry. Thus slowing down the airflow and improving material separation.

The second stage of the RAMVAC Air System takes the air from the tank and routes it into our cyclone filters. At this point, the cyclonic action of these filters propels any remaining material to the side walls of the filters and then down into an easily maintained collection box.

In the third stage of the RAMVAC Air System, the air moves from the cyclone filter into the dual 10-micron final filters. These washable filters will capture any fine particles remaining in the air stream before allowing the air to pass through the positive displacement blower.

RAMVAC’s boom features a 5′ extension for a total reach of up to 26′ from the truck. Worm gear driven, with access to the receiver box, and abrasion-resistant steel at the back to absorb the impact from bulk material. RAMVAC’s standard “dig deep” boom provides operators the ability to dig 13 feet below grade utilizing one standard vacuum tube.

The Temperature Controlled Environmental Chamber is a RAMVAC Exclusive feature. The entire water system is enclosed in this insulated, heated compartment. From the moment the water enters the top of the tanks until the moment it leaves the hose reel, every component from tank to pump is heated by our 80,000 BTU heater.

RAMVAC HX trucks come standard with locking differentials and power diverters to help you escape the most difficult terrain. Its design ensures one of the smallest footprints in the industry, allowing you to get into those tight spots where other hydro excavators will not fit.

RAMVAC Hydro Excavator’s drive system includes fail-safes that other manufacturers do not. The truck series is equipped with independent drive systems for the blower, the water system, and auxiliary hydraulics to ensure less wear and tear, as well as system separation.

RAMVAC features a NEMA 4electrical system, including a dust and water-resistant control panel, rubber booted and o-ringed controls, loomed wiring, sealed automotive-style connections and junctions, as well as a common electrical ground.