Model 747

Truck Jet

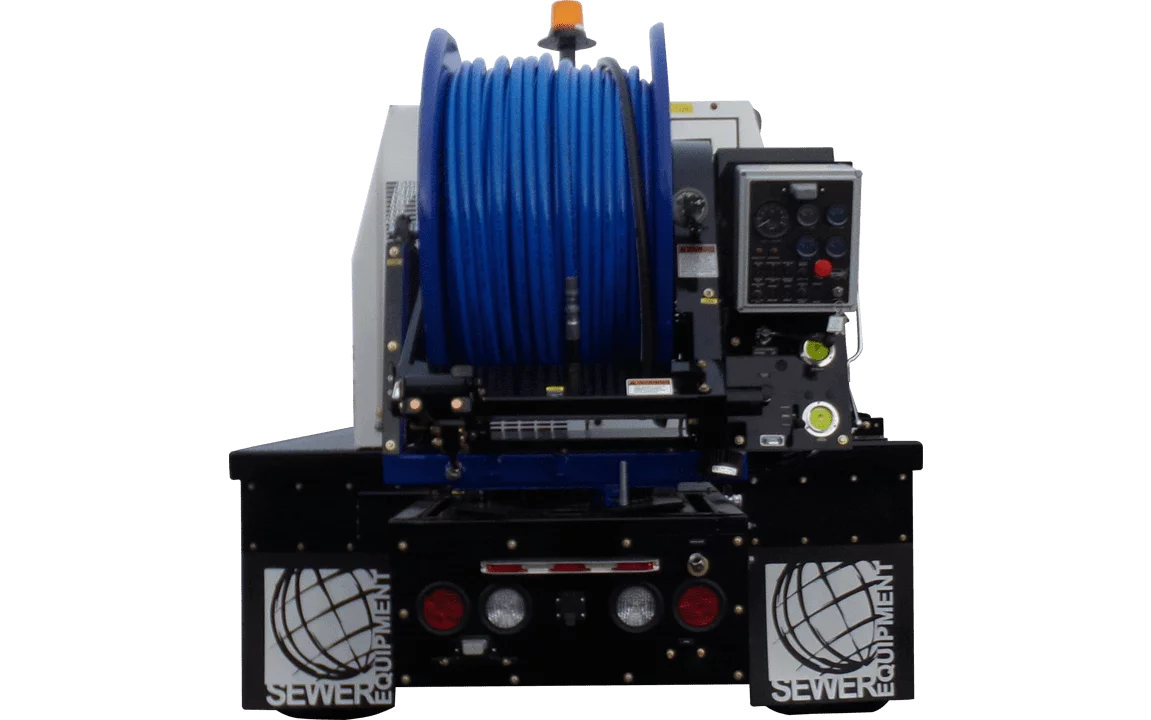

TRUCK JET MODEL 747-TK

Regardless of your requirement, a 747 can be built to meet it. If a truck, instead of trailer, is more suited to your application, the 747 is offered to mount on your chassis or a factory provided unit with up to 3,000 gallons of water capacity. When truck-mounted, power can be delivered by an auxiliary engine or via PTO hydrostatic drive from the chassis’ power plant.

BEST PRODUCTS. BEST LOCAL SUPPORT.

The Model 747-TK offers the same great features as the 747-FR2000 series, offering a Ford gas engine and Giant triplex plunger run-dry pump as standard equipment. At Sewer Equipment, we assure our customers with a vast support network, utmost performance, and reliability for the life of the machine. Frames made of fully-welded 1/4″x 2″ x 6″ steel tubing for maximum strength and durability are certified by the National Association of Trailer Manufacturers, assuring your equipment adheres to all federal D.O.T. regulations and safety standards.

WHAT’S THE BOTTOM LINE?

Like all Sewer Equipment CO. of America jetters, the 747 comes standard with our fully baffled Duraprolene water tanks, to eliminate surging while stopping and turning with water on-board. The rotating hose reel allows operators to work efficiently while positioning themselves out of traffic and other hazards, and a NEMA 4 watertight control panel is located on the hose reel, easily accessible to the operator at all times. The ECO platform allows the engine to run at 33% less RPM than traditional designs, saving on operating costs due to decreased fuel consumption and creating a safer work environment for operators due to lower noise emission.

Quick Look at Specifications

Length: 26‘2" Width: 8’4" Height: 8’6"

Axle Configurations: Single or Tandem Axle

Max Water Capacity: 700 Gallon

Max Hose Capacity: 1000’ Hose Size: 1/2" - 1"

ONE PIECE ENCLOSURE: Our one-piece enclosure is designed to maintain its cosmetic and functional integrity throughout the life of your equipment. While some manufacturers bolt individual panels together to achieve its purpose this practice leads to rusting panels, missing fasteners and overall degradation of the equipment. In addition to the structural and cosmetic integrity, these enclosures function to maintain temperatures above freezing in most conditions. With steel or aluminum available as materials of construction, our units are designed for the harshest weather and road conditions.

DURAPROLENE® WATER TANK: Many manufacturers choose to build using rotational molding. However at Sewer Equipment, we offer trademarked Duraprolene® tanks. Unlike typical “poly” materials of construction that are rotational molded and non-repairable, our Duraprolene® material can be repaired long after the warranty has expired. In addition, our design is fully baffled, yielding dramatically improved stopability. It is UV stabilized for protection from the sun and the surface is textured to provide a long lasting finish that will withstand the test of time and keep your unit looking first rate long into the future.

BOX TUBE FRAME: A steel box tube cross section is stronger than a “C” channel cross section and also leads to a stronger and longer lasting frame designed to withstand the strenuous rigors of any application you throw at it. It is for this reason we utilize this concept in all our products and provide our customers with the best value in the market.

NEMA 4 WIRING: Moisture can cause havoc on electrical systems which is why we choose to protect our electrical systems with NEMA rated enclosures. NEMA is an acronym for National Electrical Manufacturers Association and this organization specifies design criteria for electrical enclosures and their sealing abilities. Rather than just run wires to and from various devices, we choose to design our products to resist the rigors of your application by utilizing these enclosures on our products and eliminate the maintenance issues related to moisture intrusion in electrical systems which do not use these methods.

Designed for Longevity

Sewer Equipment Company of America built its first 747 Trailer Jet with a rotating hose reel in 1993. Throughout its evolution, the 747 series of jetters has been the industry standard by which others are judged. Whether it is longevity, operator safety, overall value, or available options that you are looking for, the current offering of 747 trailer and truck jets are without peer in the marketplace.

Longevity starts with choosing the proper components and continues with meticulous design and assembly. With diesel engines and triplex plunger run-dry water pumps as standard equipment, users are assured of a vast support network and the utmost performance and reliability for the life of their system. Trailer frames are made of fully welded ³∕₁₆” x 2” x 6” steel tubing to maximize strength. Additionally, they are corrosion resistant and every trailer is certified by the National Association of Trailer Manufacturers, assuring you of adherence to all Federal D.O.T regulations and safety standards.

Safety and Strength

Our stout frames limit flex and sway while towing, and our available Duraprolene® water tanks are fully baffled to eliminate surging while stopping and turning with a load of water. Once on the job, our rotating safety reel allows the operator to position the trailer in the safest possible manner while simply rotating the reel to conveniently face the access point. The NEMA 4 control panel swivels with the reel to allow safe access regardless of reel position.

Long term value is also created with design features like a welded, one piece enclosure and components that are painted prior to assembly to eliminate points of corrosion. For increased corrosion resistance, an aluminum enclosure is also available.

Built to Meet your Needs

Any machine requirements necessary to get your job done, a 747 can be built to meet it. If a truck is more suited to your application, the 747 is offered to mount on your chassis or a factory provided unit with up to 3,000 gallons of water capacity. When truck mounted, power can be delivered by an auxiliary engine or via PTO hydrostatic drive from the chassis’ power plant. Budget-minded customers can look to the 545 series, which has the same construction features of the 747, but is without an engine and pump enclosure, or with engine enclosure only. Additional machine options include various pump configurations, wireless remote controls, tool storage, dual reels, safety lighting, integral CCTV system, and more.