RAMVAC TEMPEST

INDUSTRIAL VACUUM TRUCK

RAMVAC TEMPEST INDUSTRIAL VACUUM LOADER

The Tempest Industrial Air Machine from RAMVAC represents proven state-of-the-art vacuum technology capable of removing dry and dusty materials, as well as liquids, over long distances and depths. Touting an 18 cubic yard debris box and a host of exclusive features, this unit delivers maximum vacuum power and industry-leading efficiency.

SELF-DISCHARGING AUTOMATIC FILTER SYSTEM

The exclusive self-discharging filter system on this air loader provides automatic interval cleaning of the filter house during vacuum operations. This system significantly reduces the downtime associated with premature cleaning of the baghouse when the debris box is not full. The Tempest is the only industrial vacuum truck on the market that allows operators to keep working while recognizing maximum debris capacity.

Quick Look at Specifications

Debris Box: 18 cubic yard capacity made from carbon steel with full opening rear door

Axle Configuration: Drop axle provides 8,500 pounds of additional carrying capacity

Exclusive Knuckle Boom: Articulating boom with hydraulic movement for maximum hose support

Vacuum System: 28" Hg 5500 CFM positive displacement blower through an 8" system

Filter System: Automatic interval cleaning of the bag house

Additional Features: Wireless Remote, Boom Catwalk, Hydro Excavation Package, Grounding Reel

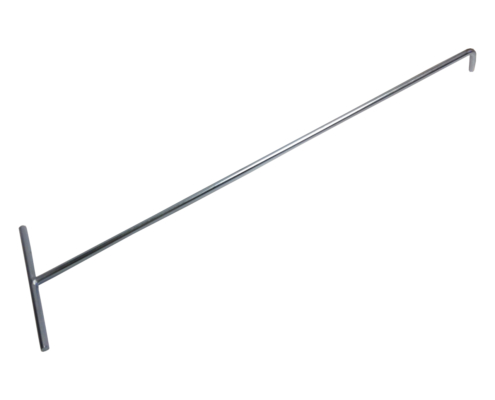

Exclusive Knuckle Boom

The Tempest‘s exclusive, articulating extendable Knuckle Boom provides 4.5’ of extension with a total 16’ working length and 270-degree range of motion. The hydraulically-powered boom knuckle hinges back and forth providing additional support of the vacuum tube. This helps by gaining increased operator ergonomics and cleaning efficiency. Pair the exclusive features of the Tempest Knuckle Boom with the industry-leading technology of the Trident Wireless Remote, operators can safely maneuver the boom from far distances to avoid hazardous environments and eliminate the need for two-man operation.

Maxium Vaccum Power

The Tempest Air Loader delivers maximum vacuum efficiency even in the toughest working conditions. While utilizing high suction from a 28” Hg 5500 CFM positive displacement blower through an 8” system, this unit also produces decreased noise emissions. Naturally, less noise leads to safer working conditions for operators. E-Stops come standard in multiple locations on the vacuum machine for the increased safety of all operators.

Unloading Efficency

Standard with a fully-opening rear door, the Tempest only requires one dump to eliminate all debris within the debris box. With a standard 50-degree dump angle and 50” clearance from splash plate to the ground, this air mover machine allows for the easy and effective offloading of material into roll-off containers or any desired dump locations.

Options to Fit Your Needs

The Tempest comes with a wide variety of options to fit the needs of every operator. The addition of a hydro excavation package gives operators access to water when the application requires it. A body vibrator helps break up dry debris during dumping operations. A boom catwalk eases overall maintenance and service and comes complete with tethered tie-offs for operator safety. As an additional safety feature, a grounding reel and spike protect against static and electrical currents while on the job.

RAMVAC AIR SYSTEM

The RAMVAC Air System is the secret behind our industry-leading performance. The RAMVAC Air System is designed to deliver industry-leading air movement while providing the maximum protection for your blower.

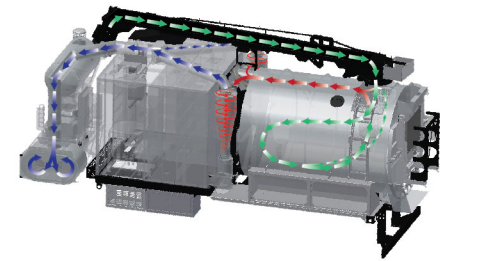

The first stage in the RAMVAC Air System is airflow through the boom. The material will impact the back of the receiver box and start to drop into the tank. As the material enters the tank, it is directed toward the front of the tank to provide for even distribution. The air entering the tank along with the material is routed from the single 8″ entry point to dual 8″ exit points located at each side of the entry. Thus slowing down the airflow and improving material separation.

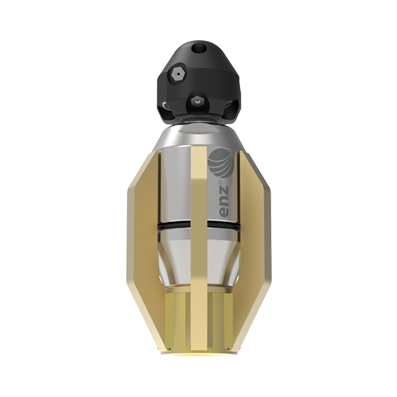

The second stage of the RAMVAC Air System takes the air from the tank and routes it into our cyclone filters. At this point, the cyclonic action of these filters propels any remaining material to the side walls of the filters and then down into an easily maintained collection box.

In the third stage of the RAMVAC Air System, the air moves from the cyclone filter into the dual 10-micron final filters. These washable filters will capture any fine particles remaining in the air stream before allowing the air to pass through the positive displacement blower.